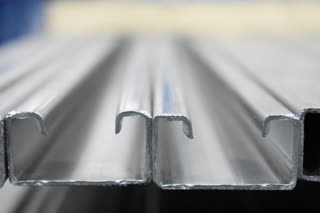

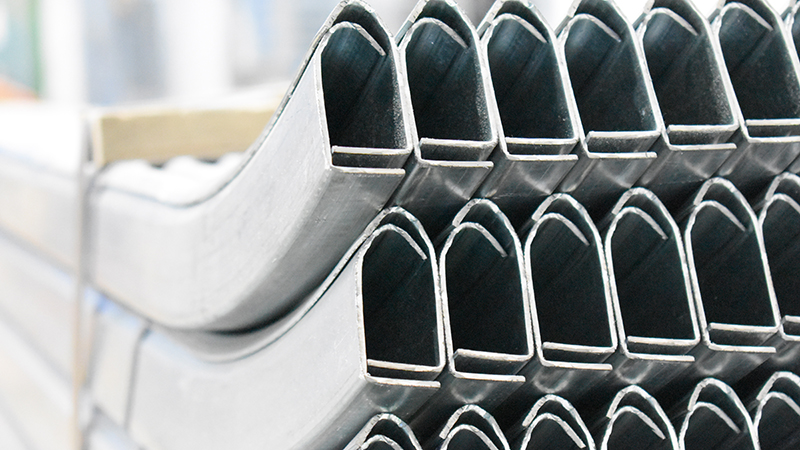

Reinforced window profiles

Our reinforced window profiles are being produced on modern rolling lines, meeting all requirements of the EN 10142 standard. We have six rolling lines and are able to produce any required amount for our customers. The profiles are made of galvanized tapes, as well as cold-rolled black sheets with the thickness of 1.0 - 2.5 mm. We produce profiles according to original documentation or the wish of the customer.We are producing more than 400 types of profiles. Among our customers, there are producers of plastic window systems, as well as final window manufacturers.

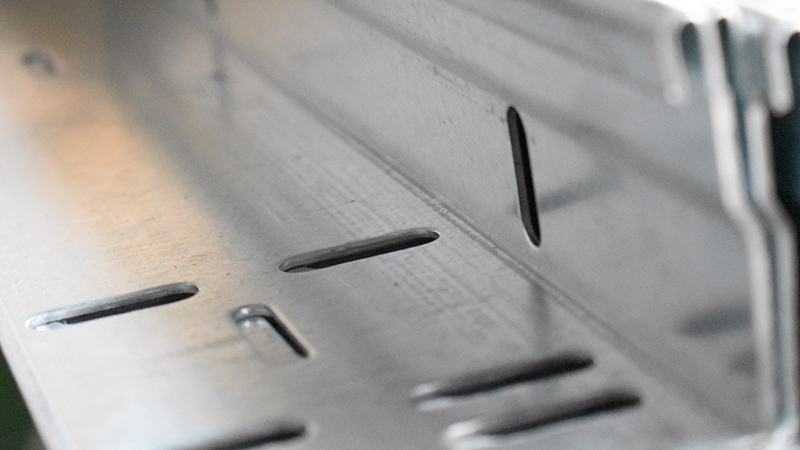

Perforated profiles

We are able to use all basic production technologies at production of perforated profiles. We use hydraulic and eccentric presses or single-use machines of our design. The profiles can be perforated during rolling, or as post-rolling process of the final product. Our equipment is able to meet the requirements of the most demanding customers.

Profiles for ducts

The profiles are made of cold-rolled steel tapes with the thickness of 1.0 - 2.5 mm. They are being used to fix AC ducts, water, sewage and heating pipes, as well as photovoltaic constructions.

Garage profiles

Profiles for section garage and industrial gates are being made of galvanized steels of the quality of DX51D Z275 - 275 g/m2 of the thickness of 1.5 - 2.0 mm. We use hydraulic presses, bending machines, or single-use machines of our design. The profiles are being produced according to original documentation.

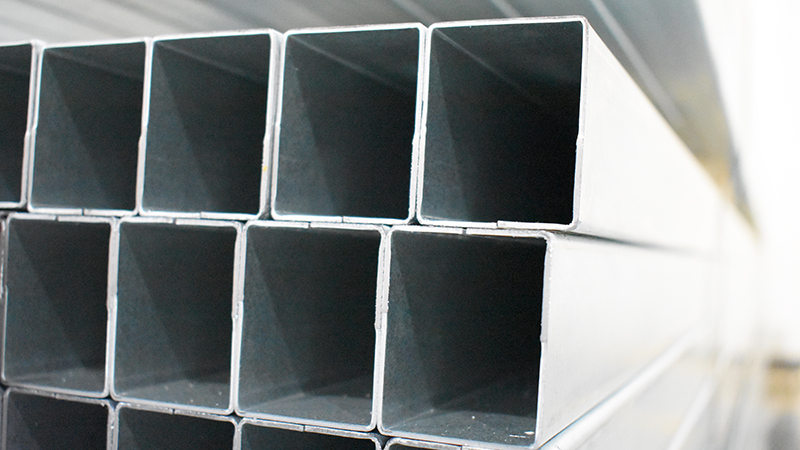

Steel tapes

We produce steel tapes on two slitters which are able to cut rolls with the following parameters: Maximum weight of roll: 8,000 kg Maximum width of roll: 1,500 mm Cutting speed: 60 m/min Simultaneity of cutting: 0.1 mm/m Sheet thickness: 0.6 - 3 mm

Plasma burning

We operate a burning machine with CNC control system designed to precise form cutting of all construction steel types. The bilateral synchronised drive of the portal on linear guide in connection with high-quality plasma system of HPR130XD provides high quality cutting and precise burning products.

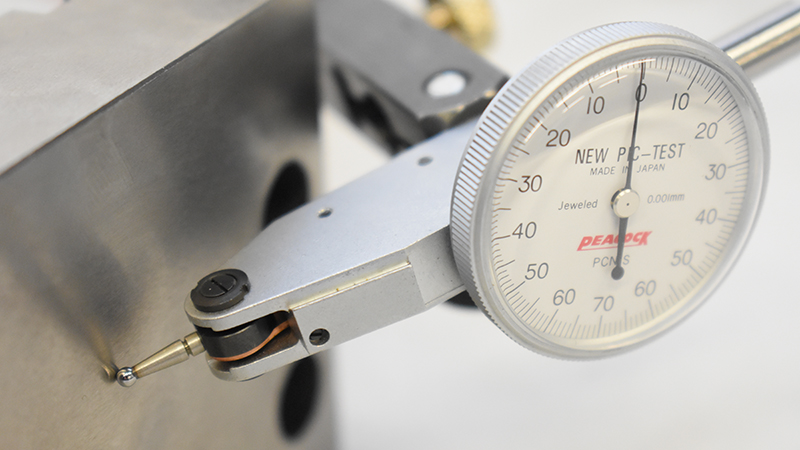

Wire cutting

We have a Japanese CNC wire cutter of the brand of Fanuc and use it to produce tools and parts of our own design. This high-precision machine (precision of up to 0.0007 mm) is able to produce very precise tools leading to supreme cutting and perforation of our products.

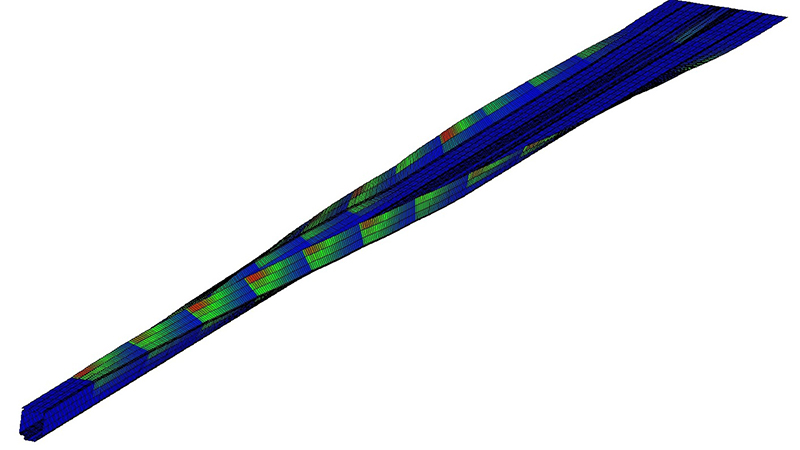

Development of profiles

Our company offers services of profile development according to the needs of our customers and the EN standards, as well. When developing profiles, we use tools and equipment of our own design. We also use a specialised computing software.